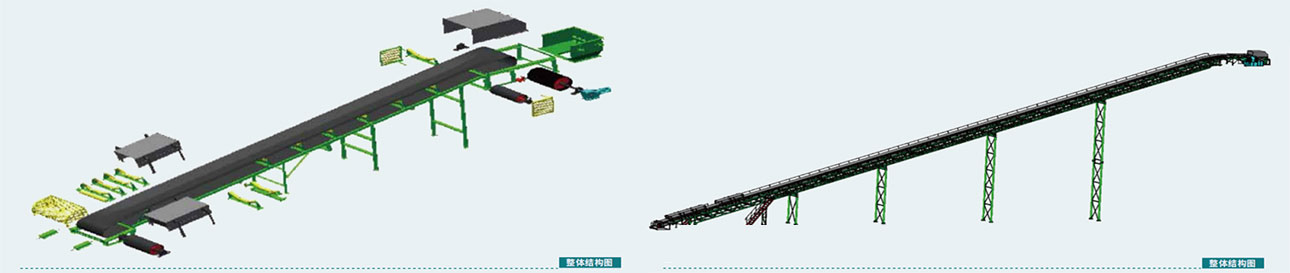

Belt conveyor overall structure as shown in figure.2. Main parts as follows Conveyor belt , driving devices(Motor, reducer, hydraulic coupling, Brake, coupling, non-return device)or Electric roller, drive roller, redirection roller, Roller, tension device, sweeper, discharger, Frame, funnel, guide chute, safety protection device.

Contact Us

| bandwidth B (mm) | Mass percentage (%) | |||

| 10 | 20 | 30 | 40 | |

| 500 | 140~90 | 130~80 | 120~70 | 100~50 |

| 650 | 210~110 | 190~100 | 160~90 | 120~65 |

| 800 | 270~130 | 250~120 | 220~110 | 150~80 |

| 1000 | 340~160 | 300~150 | 260~140 | 180~100 |

| 1200 | 390~200 | 350~190 | 300~170 | 220~130 |

| 1400 | 450~230 | 400~220 | 340~200 | 260~150 |

| 1600 | 500~260 | 450~240 | 380~220 | 290~180 |

| 1800 | 550~290 | 480~270 | 420~240 | 320~200 |

| 2000 | 580~320 | 500~300 | 450~260 | 350~230 |

| 2200 | 600~350 | 520~320 | 480~290 | 380~260 |

| Name | Bulk density x10³ kg/m³ | Angle of repos | Running direction of maximum slope |

| anthracite(piece) | 0.9~1.0 | 27 | 15~16 |

| anthracite (broken bits) | 1.0 | 27 | 18 |

| lignite blocks | 0.7~0.9 | 35~45 | 18 |

| powdered coal、clean coal、midding coal、tailing | 0.6~0.85 | 45 | 20~21 |

| raw coal | 0.85~1.0 | 50 | 18~20 |

| coke | 0.5~0.7 | 50 | 17~18 |

| coke(granularity) | 0.4~0.56 | 30~45 | 20 |

| iron ore、limestone、rock、Uniform blocks | 1.6 | 35 | 14~16 |

| crushed big small |

1.6~2.0 1.2~1.5 |

38 | 18 15 |

| dry sand | 1.3~1.4 | 30~35 | 16 |

| wet sand | 1.4~1.9 | 45 | 20~24 |

| Type waste sand | 1.2~1.3 | 39 | 20 |

| sand with grave (wet) | 2.0~2.4 | 30~35 | 18~20 |

| dry loose soil | 1.2~1.4 | 35 | 20 |

| wet soil | 1.7~2.0 | 30~45 | 20~23 |

| oil bearing shale | 1.4 | 39 | 18~22 |

| blast furnace slag | 1.3 | 35 | 18~20 |

| cement | 1.2~1.5 | 30~40 | 15~20 |

| salt | 0.8~1.3 | 25 | 20 |

| Rock and gravel | 1.5~1.8 | 30~40 | 16~20 |

| iron ore | 1.7~2.5 | 35 | 18~20 |

| iron ore stone | 2.5~3.0 | 32 | 15 |

| ouerburden material | 1.6~1.7 | 25 | 17 |

| grain | 0.7~0.85 | 24 | 16 |

| fertilizer | 0.9~1.2 | 18 | 12~15 |

| Type | The tensile strength | Width | ||||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | ||

| woven | CC-56 | √ | √ | √ | √ | √ | √ | |||||

| nylon fabric | NN-100 | √ | √ | √ | √ | √ | √ | |||||

| NN-150 | √ | √ | √ | √ | √ | √ | √ | |||||

| NN-200 | √ | √ | √ | √ | √ | √ | √ | |||||

| NN-250 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| NN-300 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| poly | EP-100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| EP-200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| EP-300 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| steel core belt | st630 | √ | √ | √ | √ | √ | ||||||

| st800 | √ | √ | √ | √ | √ | √ | ||||||

| st1000 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| st1250 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| st1600 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| st2000 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| st2500 | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| st3150 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| st4000 | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| st4500 | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| st5000 | √ | √ | √ | √ | √ | √ | √ | √ | ||||

The company has advanced production equipment and professional technical team, and is committed to the research, development, design, production and sales of various conveying equipment; The company has the ability to design and manufacture all kinds of conveying equipment and the ability to develop and innovate all kinds of parts, which can be customized according to customer needs.

Discover More